(864) 249-0943

(864) 249-0943

November 18, 2019

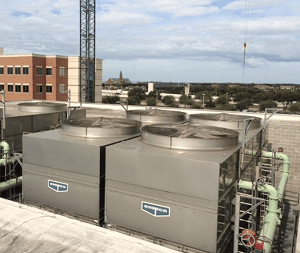

There are many different types and variations of cooling towers, below we’ll cover eight different types. With so many options it can be confusing and hard to figure out which is best for you. The list below will inform you about the different types and will hopefully give you a better understanding of what type may be best for you.

1. Packaged Type - These types of cooling towers are assembled at a factory and are smaller than field erected towers. Since these are smaller they only come in tonnages up to around 1,500 per cell. They are typically used at places that have a smaller chilled water requirement. It could include; chemical plants, hotels, malls, hospitals, manufacturing plant.

2. Field Erected – These are much larger in size than the packaged tower types. They have a much greater cooling capacity. They are shipped to the site in pieces and assembled there. They are not able to be transported by truck once assembled. Power plants, petroleum sites and others like these are where these are typically used.

3. Natural Draft Cooling Towers -These are typically very tall, shaped like a chimney, and are concrete. These are often used at nuclear power plants. The warm air naturally rises due to the cool, dry air outside. The warm air rises and draws air to the top of the tower where it is released.

4. Mechanical Draft Cooling Towers – These towers have a fan in the top of them and pull in air from the side or bottom. The dry cool air outside is pulled in through the fill. Once it reaches the middle of the tower the warm moist air is blown out the top by the fan.

5. Open Loop Cooling Tower - In an open loop system the water being used in the process flows through the tower exposed to the outside elements and is a part of the evaporative cooling process.

6. Closed Loop Cooling Towers - In a closed loop tower there is a tube bundle in the top of the tower. The working fluid flows through the tube bundle. Water is sprayed over the tube bundle and the fan pulls air across it for cooling. This type of tower protects the working fluid from exposure to the outside environment and eliminates contamination.

7. Crossflow Cooling Towers - Crossflow towers have water enter on each end of the tower. The air is drawn in from the sides, perpendicular to the flow of water. The air continues through the fill to the middle of the tower where the fan pushes it out the top.

8. Counterflow Cooling Towers – The air is drawn in from the bottom and moves in the opposite direction of the water. The water is sprayed in near the top of the tower onto the fill. The warm moist air moves through the fill and is pushed out the top by the fan.

Our business is buying, selling and decommissioning but our foundation is people.

You are first. Always. We seek to serve you with integrity, honesty, and the utmost customer service.

Our approach is different. Relationship over transaction. We are committed to embracing the challenge until we have the best solution for you.

WE ARE LEL.