(864) 249-0943

(864) 249-0943

April 3, 2017

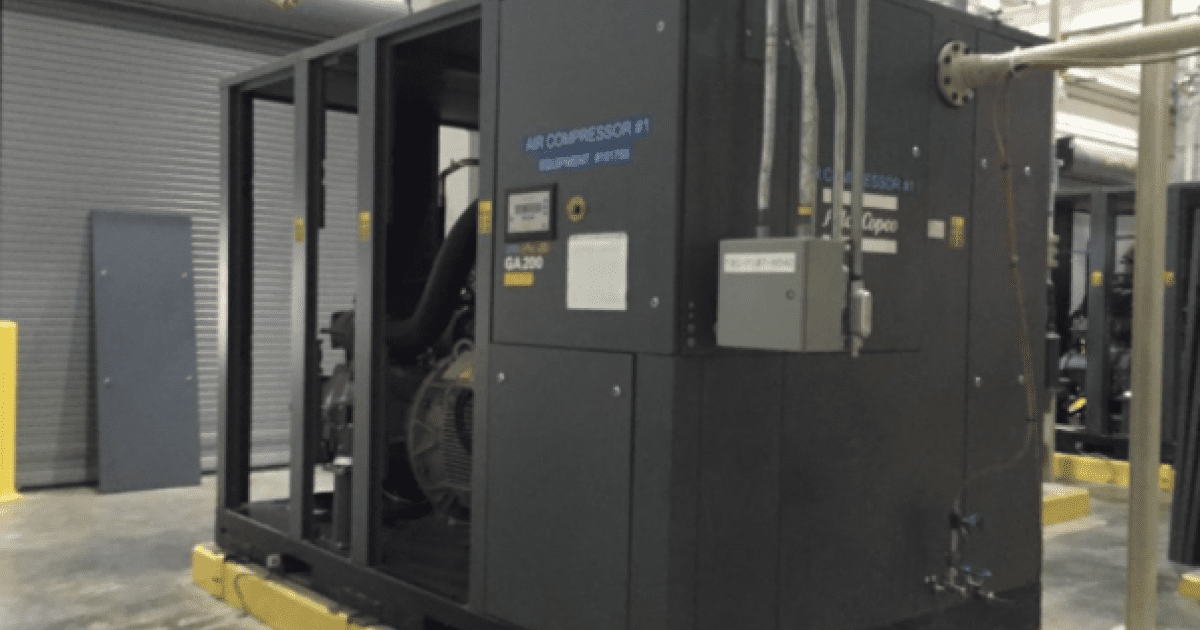

Preventative maintenance is the best and most efficient way to maintain your equipment. For industrial air compressors, the benefit of adhering to a preventive maintenance schedule far outweighs the cost of waiting until corrective maintenance is required. Following a scheduled plan will help you to detect when your air compressor parts will need to be replaced before they malfunction, therefore, saving you time and money. Utilizing the following chart will help ensure that your industrial air compressor remains in great working condition for many years.

-Always shut off main power when air compressor is not in use

-Allow components to cool before servicing

-Always refer to operating instructions when performing maintenance

As with all industrial equipment, appropriate maintenance intervals may vary based on specific environmental and operational conditions. The key is to engage in preventive maintenance regularly enough to find potential problems before they are in need of major repair or replacement. By consistently and diligently performing preventive maintenance on your compressed air system, the high cost and unnecessary downtime that results from corrective maintenance can largely be avoided.

Our business is buying, selling and decommissioning but our foundation is people.

You are first. Always. We seek to serve you with integrity, honesty, and the utmost customer service.

Our approach is different. Relationship over transaction. We are committed to embracing the challenge until we have the best solution for you.

WE ARE LEL.